Containing your working zones thanks to a modular concept

Simple modular concept, which is quick to deploy and will safely contain working zones

-

The aim is to filter particles, very small size pollutants (submicronic, virus, etc).

Design a controlled-environment chamber which is quick and easy to deploy to:

- Contain the working zone and avoid, as preferred:

- discharging contaminants outside the chamber,

- introducing contaminants inside the chamber.

- Protect the working environments, populations, operators and the natural environment,

- Take emergency action.

Contaminants can include dust up to submicronic particles, chemical or radiological pollutants, and even virus.

- Contain the working zone and avoid, as preferred:

-

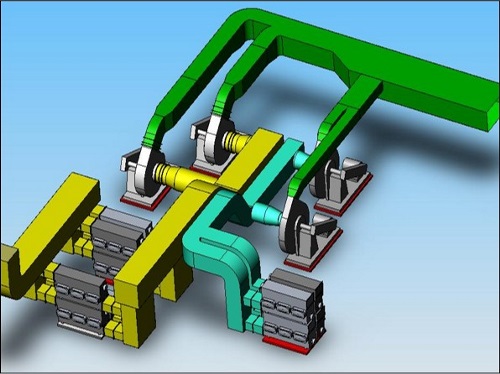

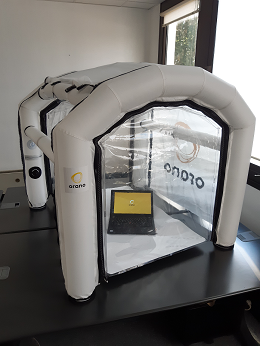

Orano has developed a modular concept made of an inflatable chamber with a controlled environment, which is portable, light and quick to deploy (less than one hour).

The secure concept is based on past Orano experience with containment principles, as applied at nuclear sites.

Just like a clean room, the controlled-environment chamber is fitted with a negative or positive pressure ventilation system to guarantee containment (particulate filtration, relative humidity/pressure management).

This inflatable structure houses a single-use disposable chamber, which can, alternatively, be re-used after decontamination. The layout of the structure and the chamber can be modified with no size limitations.

- An effective containment, which is simple and light to set-up,

- Assembly taking just 40 minutes

- Modularity, possibility to adapt to meet the needs of activities (1 m2 to 100 m2)

- The vinyl airlocks can be considered as single-use items or re-usable

- Compliance with ISO standards on containment enclosures and nuclear ventilation systems

-

- Contained chamber with an inflatable structure

- A structure which can be deployed in just 40 minutes

- Modular customisable structures ranging from 1 to over 100 m² (Custom design)

- Over 99% of submicronic particles (e.g. virus) are filtered

- Chamber pressure range: from –50 Pa / P Ext to +50 Pa / P Ext

- Humidity management

- Remote management of various operation functions

- Can be used in many business segments: healthcare, hospital environment, pharmaceutical industry, electronics, aerospace, fine chemicals, biotechnology

-

-