Designing and programming Instrumentation and Control systems

Proposing solid Instrumentation and Control (I&C) systems integrating safety requirements from feasibility studies up to process commissioning.

-

Be equipped with an instrumentation and control system able to meet:

- process-related needs while guaranteeing the operating domain

- the needs of operators to ensure efficient and safe handling

- the requirements of standards, particularly safety standards for sensitive processes

- reliability and availability requirements for the installation

- cybersecurity requirements

- requirements in terms of through-life support and operating safety.

-

In order to answer to the requirements:

- Take action from the design phase through to on-site delivery, integrating design, programming and testing for instrumentation and control software

forsystems and providing through-life support and security for facilities. - Propose solid technological solutions specifically designed for the nuclear segment while integrating innovative technologies (wireless architectures, standalone sensors, smart sensors, etc.) to optimise facility operations and plan ahead for operating needs.

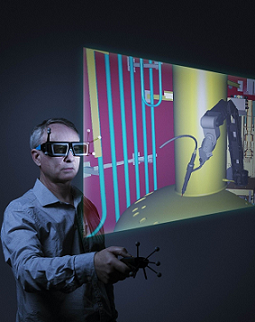

- Make available to operators a human-machine interface (ergonomics) allowing an optimized monitoring of the process

- Technical solutions built on solid know-how and feedback thanks to the many past achievements at group plants, run with close cooperation between engineers and operators.

- Management of all project phases: from design studies up to on-site installation, including the development phase and testing of instrumentation and control software

- Finding the right level of compromise between solidity and innovation

- Take action from the design phase through to on-site delivery, integrating design, programming and testing for instrumentation and control software

-

- Studies & design of instrumentation and control systems and safety systems (according to the requirements of SIL standards)

- Instrumentation specification and regulations

- Specification of software for automation projects (HMI, automaton) and the selection of tools

- Service specifications for production and installation sub-contractors, and tracking during production

- Design and programming of industrial IT, supervision and automatic control software (PLCs and SNCC)

- V&V (Verification & Validation) processes and requirement traceability

- Platform test specifications and completion

- Site incorporation, testing and testing assistance

- Equipment qualification in conditions specific to the nuclear environment

- Qualification of instrumentation and control hardware specifically for use in the nuclear sector

-

-