Decreasing the volume of radioactive effluents

Safe and efficient solution to minimize the volume of your high active liquid waste storage before ultimate conditioning.

-

High Active Liquid Waste (HALW) management needs:

- Concentrate HALW into a manageable volume for temporary storage and optimize concentration in order to prepare final conditioning,

- Demonstrate to Safety Authorities their safe management,

- Design process and equipment remotely operable, inspectable and maintainable allowing management of the decay heat,

- Design equipment compatible with lifetime needs and remaining space in the area, and as cost-effective as possible.

-

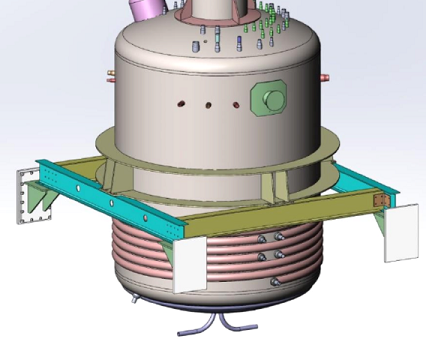

Evaporation of HLW in specifically tailored evaporators is a very efficient solution to concentrate such waste.

A wide range of evaporators and evaporation units have been developed by Orano since the 1960s and are regularly optimized taking into account operator feedback, R&D progress, advances in technologies and regulations, and specific operator constraints and requirements.

Safe and cost effective volume reduction of HALW allowing easier storage management and optimized final conditioning process.- Significant volume reduction (by a factor 10-100 according to waste),

- Concentrates ready for transfer to storage and final conditioning, including any suspended solids

- Acids/bases recovery for recycling achievable,

- Recovered water decontaminated to desired level, down to site low-level thresholds if need be,

- Chemical hazards analyzed and taken care of in the process and equipment design to ensure safe operation,

- Nuclear hazards (including criticality, decay-heat, radiolysis, contamination and irradiation) analyzed and taken care of in the process and equipment design to ensure safe operation,

- Remote inspection of pressure vessels possible,

- Proven safety, operability and maintainability (60 years track record),

- Solutions tailored to the exact customer need (type of waste, type of hazards, activity level, required throughput, layout constraints, site configuration, life-time requirements, life-time increase…),

- Expertise and R&D knowledge, design, manufacturing and operation expertise provided throughout the customer’s project.

-

- Proven safety and reliability

- Volume reduction

- Management of suspended solids, precipitates or foams

- Concentrates ready for conditioning

- Reagent recovery and recycling

- Distillates ready for site liquid waste facility

- Operable, inspectable, maintainable, and adaptable facilities

-