Leaching: a solution adapted to your ores

Leaching: a solution adapted to your ores

-

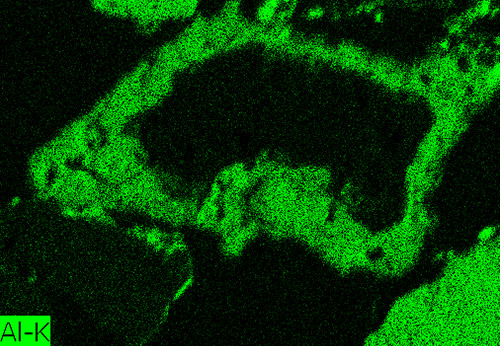

In a deposit, the ores consist of different metal elements that are more or less difficult to dissolve; this dissolution is necessary for their extraction and recovery. To exploit a deposit optimally, it is therefore necessary to determine the performance of the different possible solution processes (leaching) and the most suitable reagents. The challenge is to determine these parameters to ensure the greatest profitability of the operation.

-

CIME has the necessary equipment to carry out leaching under different conditions: in dynamic mode (agitated tanks) or in static mode (heap leaching or In Situ Recovery), pressure (autoclaves), atmospheric pressure, ambient or high temperature.

- Performance analysis and consideration of potential gains

- Consulting (decision support) on the most suitable process according to the operating conditions

- Setting operational parameters for productivity and economic gain

-

- A wide variety of equipment (autoclaves, tanks, columns, mixers, agglomerators, presses, etc.) allowing all types of leaching to be tested.

- Three laboratories dedicated exclusively to leaching.

-

-

-