Management of Radiolysis Inside Closed Systems

Orano NPS’s Oxide Getter allows to manage radiolysis in a very-closed environment, as inside a cask for spent fuel or waste, by fully absorbing hydrogen potentially releasable. It is effective with different types of materials.

-

The radiolysis phenomenon and the thermolysis of organic material are of great importance in waste conditioning. The evaluation and, may be, mitigation of hydrogen generation inside a package are necessary to ensure that a flammable mixture is not formed, by verifying that casks do not accumulate an unsafe concentration of hydrogen (H2 Lower Flammable Limit, LFL < 4% vol. at room temperature in air).

This happens when water is present and radioactivity is sufficient to start water radiolysis with release of hydrogen. Water can be free water, contained in the material or adsorbed on it.

When organic material is present, hydrogen can be produced by disintegration of the material under radiation exposure.

-

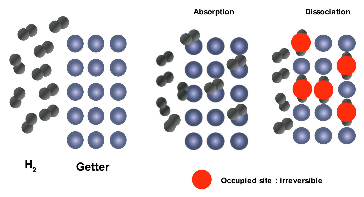

An industrial, simple and performant solution to eliminate the hydrogen produced by a material consists in hydrogen absorption onto oxide getters. The hydrogen so absorbed by the getter is chemically bound into a crystalline structure, in irreversible way for current operating temperatures (up to 400 °C).

This solution is very effective to eliminate H2 in closed spaces such as casks for spent fuel or waste. Its compactness and its capability to be shaped make it adaptable to different geometries, including encapsulations.

It is also effective for very-long interim storage.

Orano NPS offers all-inclusive services associated with its Oxide Getter: from design to product delivery, licensing support and maintenance.

- Main advantages:

- compatible with dry transport and interim storage

- valid for all contents releasing H2

- safety margin increased during transportation, to fulfill ‘Lower Flammability Limit’ criterion for H2 in air (4 % at ambient temperature)

- no reduction of waste filling-volume in the cavity: compact and versatile system, adaptable to many types of packages

- no need to re-open the cask lid

- Reducing drying time in case of continuous evacuation

- High predictability and effectiveness for long period of storage:

- Hydrogen is fully absorded on the getter, with no release of hydrogen outside the closed space

- effective at high temperature and γ-radiation level

- mineral oxide getter guarantees no chemical interaction with the package content, in most gaseous environment

- getter is replaceable in case of possible saturation

- Main advantages:

-

- Very effective absorption with no further hydrogen release

- 1 kg of Orano NPS’ Oxide Getter absorbs:

- the quantity of H2 produced by 75 g of water

- 100 liters of H2 produced by polyethylene (at normal conditions: 1 atm, 20° C)

- Extreme operating conditions:

- up to 400°C

- under high gamma-radiation up to millions of Gray

- Mineral oxide guarantees no chemical interaction with the package content

- No ageing effect

- Compatible with most gaseous environment

- Versatility:

- Compact, ideal for tight spaces

- Multiple shapes