Skid containers: Tests and laboratory for on-site piloting

Tests and analyses directly on your site, adapted to your needs

-

To design, develop and size a new hydrometallurgical process, laboratory tests and pilots are required. These tests are usually carried out using synthetic (simulant) solutions whose characteristics are very close to the real solution. In order to approve the results observed experimentally in the laboratory, it remains essential to reproduce them on real matrices, on the site where they are produced, which constitutes a challenge. In fact, customer sites do not generally have the infrastructure necessary to carry out these experiments.

-

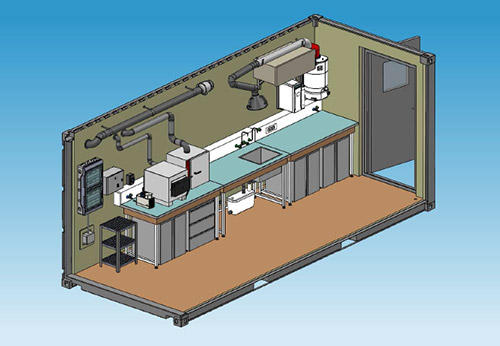

To gain efficiency and work directly on the matrices to be considered, two Iso-20-foot containers have been built and equipped by CIME to pilot on site: a skid test container and a laboratory container. These containers allow processes to be defined for the extraction/recovery of metallic elements such as thorium, rare earth or other elements of interest (cobalt, copper, nickel, vanadium, molybdenum, etc.) directly at the production site.

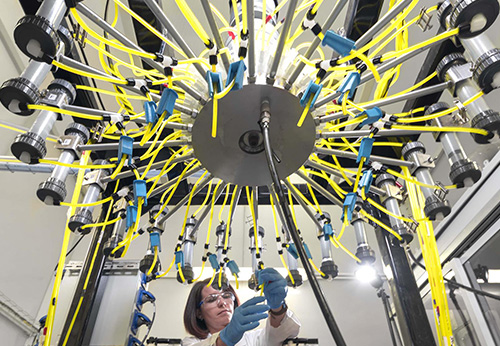

- The skid test / control container is equipped with 4 removable units, ventilated, equipped with a flexible stainless steel structure, on which can be fixed different laboratory equipment (mixers-decanters, agitation motors, etc.) chosen according to the specifications provided. Continuous operation is possible (3*8 hours, 5*8 hours) and monitored by technicians.

- The laboratory container allows the first bench tests to be carried out which then point towards a pilot diagram. It is equipped with demineralised water station, ventilation, compressor and vacuum pump. Other equipment can be added according to the requirements for the proper conduct of the tests (portable XRF, colorimeter, turbidimeter, thermobalance, densimeter, titrator, etc.).

These two containers allow the completion on the production site of the different hydrometallurgical stages essential for the recovery of the metals of interest (leaching, separation S/L, SX, IX and/or precipitation), while taking into account the presence of elements that can strongly impact the process: MES, mineral fines, viscosity, impurities (arsenic, etc.). Thanks to the on-site testing with the skids, a technical, innovative, economical and directly applicable solution can be proposed.

- Conduct of tests on actual matrices to be treated (PLS, waste, sludge, ores, residues, etc.): the impactful elements are present and their management is therefore properly taken into account (presence of silica/fines, chloride/sulphate content, high acidity, etc.).

- Close collaboration with the customer: adaptation to changes, rapid approval of the different stages, co-development, etc.

- Possibility of back up with the CIME analytical laboratory in the event of a complex study.

- The skid test / control container is equipped with 4 removable units, ventilated, equipped with a flexible stainless steel structure, on which can be fixed different laboratory equipment (mixers-decanters, agitation motors, etc.) chosen according to the specifications provided. Continuous operation is possible (3*8 hours, 5*8 hours) and monitored by technicians.

-

- Range of flow rates for tests that can be carried out on the test bench: from 20 mL/h to a few L/h

- More than a dozen available technologies that can be installed in skids

- Customised adaptation to test requirements and analytical monitoring

- Robust equipment (adaptation to climatic conditions)

- Limiting chemical or radiological risks related to transport

- Compliance with safety criteria and environmental standards

-

-

-