Reprocessing to master used fuel management risks

Used fuel reprocessing offers several benefits for operators, reducing risks and costs and allowing safe and long-term storage of waste conditioned in a universal canister offering geological repository design and operation rationalization.

-

In a context where operators and organizations in charge of used fuel management face several challenges such as saturation of the pools, delays of final disposal projects, necessity of multiple operations related to the management of interim storage (Issues with fuel integrity for extended dry storage period, ageing management with potential reconditioning required, repacking into final disposal canisters…)and are required by local or international authorities to define a used fuel management strategy up to disposal, used fuel reprocessing is a way to implement a safe, cost effective and sustainable strategy. This allows an optimized management of conditioned waste to be placed in future geological disposal facilities and the reuse of recyclable materials still contained in the used fuel, thus saving natural uranium resources and increasing the energetic independence.

-

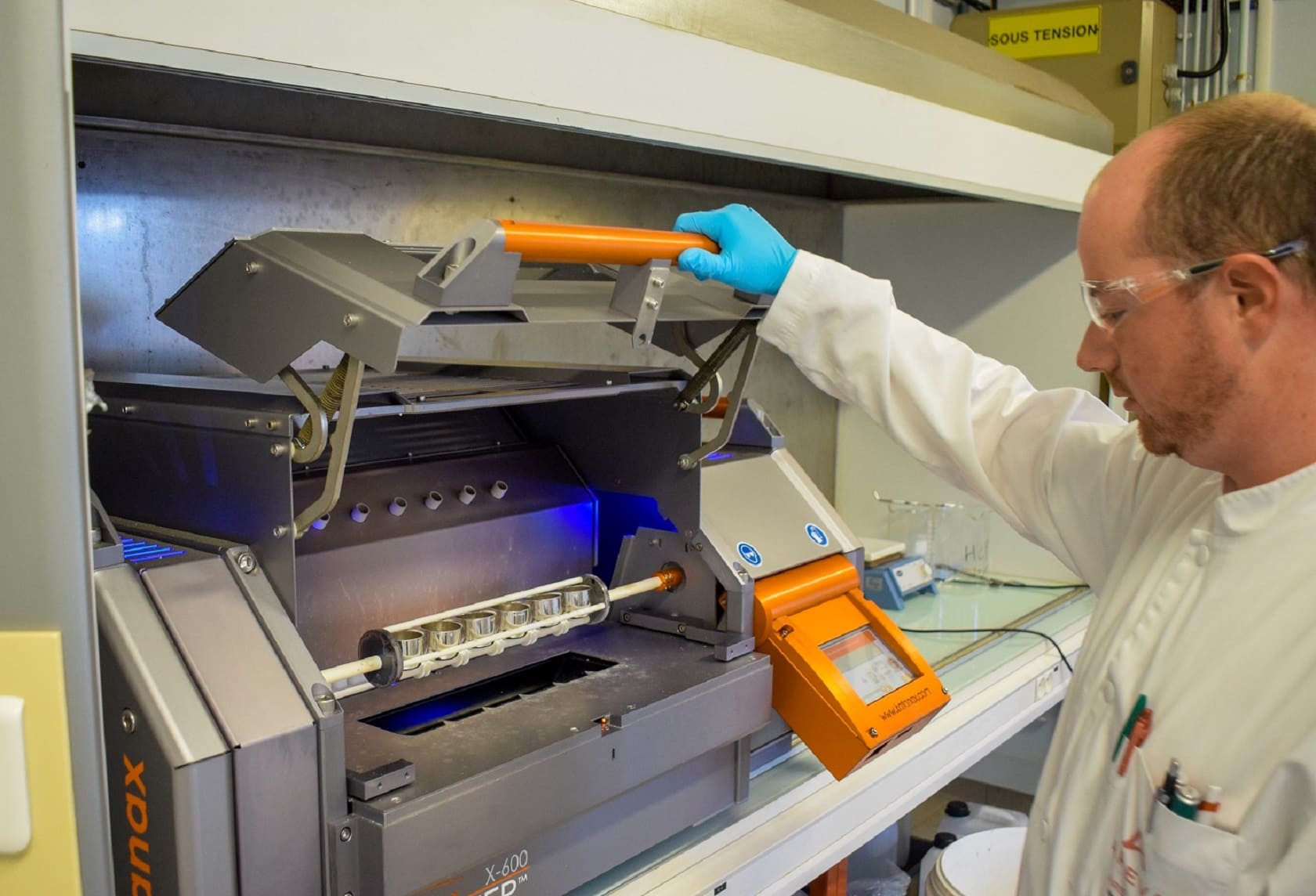

Used fuel reprocessing is a mature technology implemented since decades by international nuclear operators leading to optimized waste conditioning.

Reprocessing is performed in the Orano La Hague facility with:

- the extraction of the recyclable materials (U & Pu) from the used fuel, representing 96% of nuclear materials contained in used fuel;

- the conditioning of the non-recyclable materials considered as waste (fission products representing 4% of the nuclear material & non soluble metallic parts) in respectively vitrified and compacted Universal Canisters.

Advantages of such Universal Canisters:

- reduction of radio-toxicity of the waste by a factor 5 (removal of fissile material);

- long-term stability of the waste (vitrification of fission products) conditioned in a glass matrix specifically designed for durability over thousands of years;

- standardization of the waste form with metallic compacted waste conditioned in same Universal Canister than the vitrified waste;

- waste stability allowing safe storage and transportability to disposal after storage

- compatibility with geological disposal projects such as the Andra’s underground radioactive waste repository project, Cigeo, in Bure (France);

- optimization of the design of disposal facilities, simplification of handling operations, reduction by a factor 10 of the volume needed for disposal and minimization of requirements for IAEA safeguards (no fissile material in the waste) including post closure;

- universality of the canisters facilitating compatibility with shared repository solutions;

- a globally strong risk reduction approach for the management of HLW waste.

Fissile materials management relieving operators of any responsibility regarding the management of the recovered materials, U&Pu.

High visibility and predictability of the costs avoiding the covering of future uncertain expenses inherent to open cycle used fuel management options (cost for initial interim storage, provision for extended storage and ageing management, potential reconditioning required etc…)

Secure & Rationalize deep geological repository by conditioning HL waste in a concentrated, stable and standardized form relieved from IAEA safeguards thus reducing the risks associated with long-term management of radioactive materials and leading to strongly optimized disposal facility.

-

Orano Reprocessing services of used fuel comprises the following steps:

- used fuel shipment to Orano La Hague reprocessing plant;

- used fuel reprocessing separating the recyclable materials (U& Pu) from the waste;

- recyclable materials (U& Pu) can be returned to the operator or can be recycled under MOX fuel and ERU fuel for the operator reactors or for third party civil nuclear reactors;

- conditioning of the waste (fission products are concentrated and vitrified, non-soluble metallic parts are compacted) in Universal Canisters, stored on Orano’s site for cooling before being returned to the country of origin.

-