Controlling the ageing of equipments and plants

Engineering study methodologies and expertise on equipment durability, aiming to roll out the action and monitoring plans necessary for productivity, quality, regulations and safety authorities.

-

For hostile zones,

- During the design phase, be familiar with and choose:

- The mandatory materials (and related recommendations),

- The equipment and systems requiring designs which allow field operations and changes during plant lifetime.

- During the operating phase, design and set up monitoring plans to prevent complex ageing situations and target and anticipate key field operations.

All this must be done in a context where the investment and operating cost must be consistent with future industrial operation, safety and changing regulatory requirements.

- During the design phase, be familiar with and choose:

-

In response, Orano can conduct:

- Functional analyses aiming to choose the material, guide the design of the equipment and layout and the functioning of the processes,

- Solution optimisations and qualifications through R&D programmes (definition/follow-up of engineering studies and calculations),

- Proposals for targeted monitoring plans and expert assessments/diagnostics on focus areas, with support from:

- Technology watch,

- Leveraging 40 years’ experience in the supervision of in-service plants (test coupons and specimens, non-destructive examinations),

- The field works carried out in partnership with other industrial operators,

- The experience gained from equipment inspection and surveillance proposals submitted from the design phases.

Organisation in project mode enables the use of additional skills in the same field, from engineering studies to tests and laboratory trials via models and calculations in support of demonstrations.

- Access to more than 40 years engineering experience on the durability of installations and equipment, in full compliance with the most stringent standards and regulatory oversight requirements,

- Field works accomplished within a project framework leading to choices targeting the best needs, cost and schedule trade-off,

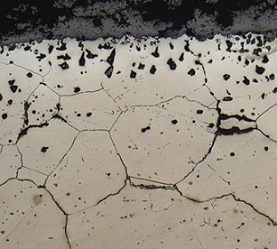

- Wide range of technical skills and expertise at the service of customer needs (corrosion, thermal calculation, structural calculation, mechanical behaviour, behaviour under irradiation, etc.),

- Access to Orano-specific operational resources and test platform to address ageing-related themes (specific test bench development, electrochemistry, corrosion, etc.),

- Demonstrations of efficient equipment and plant performance to guarantee intended service life and prolong it.

-

- Methodologies proven in Orano’s facilities

- Strong expertise combined with solid experience feedback from plants in operation or being dismantled

- Services covering the whole life cycle of a solution: from R&D, implementation, in-service monitoring, reliability enhancement, dismantling and experience feedback integration

- A variety of engineer profiles covering the wide range of materials (metallic, organic and non-organic) and their ageing in corrosive or radio-oxidising environments or high-stress mechanical conditions

-

-