Design and qualify remote non-destructive testing solutions

Orano designs, develops and deploys methodologies and remote-operation tools to perform Non-Destructive Tests (NDT) in hostile zones inaccessible to humans.

-

During the operating phase, changes in equipment ageing or specific situations may call for customised testing resources to be deployed in hostile/irradiating and/or restricted-access zones.

This calls for the development and qualification of:

- testing operations in hostile zones, on equipment for which monitoring was not anticipated at the design stage,

- new, higher-performance testing methods.

-

By deploying its wide-ranging NDT skills, Orano is able to perfectly customise testing solutions to your equipment in hostile environments:

- Identifying zones of interest and specifying types of testing

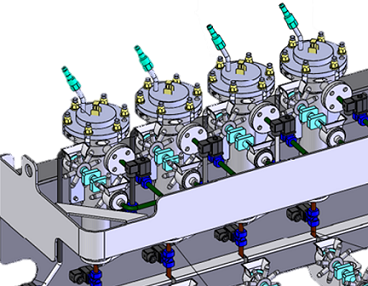

- Accomplishing services, from the design to the commissioning of a new testing equipment package

- Customising existing NDT technologies like:

- Visual inspection by HD camera or muon imaging

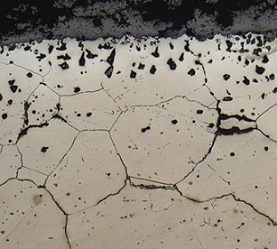

- Thickness measurement and defect search using Ultrasonic Testing (single-element or multi-element probe) or Eddy Current Testing

- Surface condition analysis (profilometries)

- Chemical analysis by remote Raman spectrometry (without sampling)

- Vibration analysis to identify a failure in a mechanical process

- Use of remote-controlled tools (drones, motor-operated poles, motor-operated trolleys, remote manipulator arms, inspection pigs, etc.).

Organisation in project mode enables the use of additional skills with the same purpose, from engineering studies to tests and laboratory trials via models and calculations in support of demonstrations.

- Controlled development work to deploy testing methods in hostile environments

- Qualified field operation procedures

- Operator training on life-sized test mock-ups

- Responsiveness and support for on-site deployment

- Creativity and innovation to design and roll out customised technological solutions

-

- Multi-skill team: mechanical engineering, robotics, field operations in hostile environments, materials expert assessment, non-destructive testing,

- Many use cases deployed on a variety of Orano sites,

- A test hall at Beaumont enabling design and implementation up to industrial scale,

- Management in project organisation mode, from design to implementation and entry into operation,

- High responsiveness to meet customer requirements.

-

-