Developping processes and technologies at HRB

A unique combination of means and expertise to develop new processes and technologies up to full industrial maturity.

-

Access human resources able to handle simple-but-exacting development and qualification needs or tackle complex, multidisciplinary assignments.

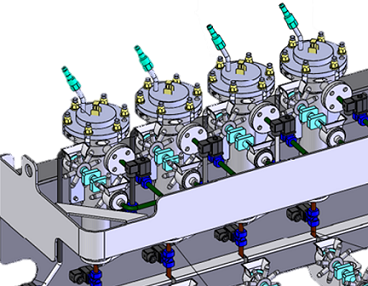

Use adaptable workspaces offering multiple capabilities (chemistry, chemical engineering, mechatronics, instrumentation, etc.) for developing, qualifying and industrialising processes and technologies in a secure work environment able to accommodate even very large prototypes.

Deploy processes & technologies in a dedicated enclosed space (sized to suit the stated needs).

Ensure "right first time" commissioning of processes & technologies for industrial projects that require it.

-

Beaumont Research Hall (HRB) is an Orano technical facility routinely used to design, develop, optimise and industrialise processes and equipment, whether deployed and in service at our plants or innovative and used in other environments.

This 3,000 sq. m hall features:

- Approximately 40 configurable test areas,

- 5 inspection pits,

- 3 handling cranes (kN),

- Utilities (water, electricity, compressed air, liquid waste treatment, etc.)

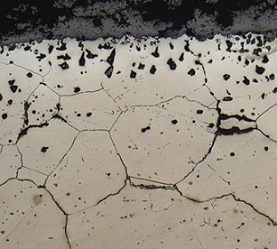

- 1 chemical and analytical laboratory,

- 1 materials laboratory,

- 1 cementing laboratory.

HRB staff can address your needs while working closely with Orano Projects’ many business units and experts (in chemical and process engineering, corrosion, electrochemistry, cementing, hydraulics, mechanics, robotics and instrumentation).

A team of designers is available onsite to design equipment.

- Modular test platforms, supported by 5 pits and 3 overhead cranes in an industrial environment

- Multi-format sample characterisation equipment

- Support provided by a multidisciplinary team of around 100 people

- Expertise in processes and technologies up to industrial scale

-

- More than 40 years of experience in processes and technologies development and industrialization,

- Support of a large expert network,

- R&D management in a project organization,

- Invaluable experience in coordination between engineering and plant operating teams, research institutes, regulator.

-

-