Modelling the impact of a fire on industrial facilities

Artificial intelligence in support of fire modelling to perform risk studies of your industrial facilities.

-

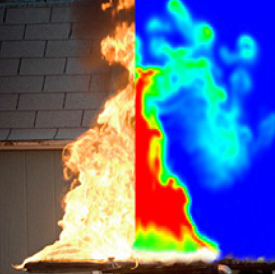

Fires have always been part of major risks associated to industrial plants.

Fires can be initiated in different ways, in very different rooms (electrical cabinet, electric cables, liquids, etc.) and of various sizes and shapes that are often under-ventilated.

Accurate fire modelisation is a major stake for risk studies and to take into account requirements safety (compliance with sectorisation, compliance with various thermal criteria, and efficiency of inerting process).

-

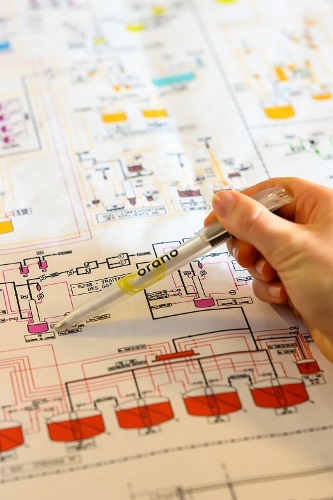

Orano has developed study methodologies, based on fire modelling, that take advantage of a panel of software and artificial intelligence.

These methodologies have been validated by comparison with experimental measurements from publications, using three methods:

- Rapid studies, using CFAST software

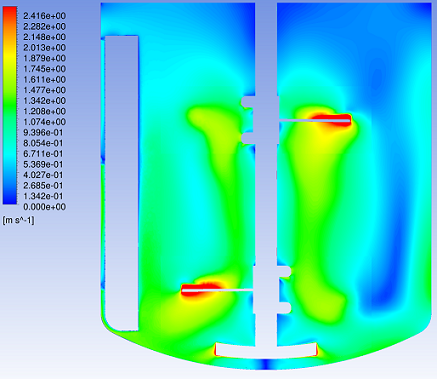

- 3D studies, using FDS software

- Studies based on an automatic experimental design making it possible to perform massive sensitivity studies (~100,000 calculations per study). This type of study makes it possible to check the impact of many parameters (material properties, levels of unburnt substances, radiative fraction, chemistry, etc.).

- Solid expertise in the field of fires

- Strong responsiveness due to our software panel and artificial intelligence

- Help to conception facilities and risk management

-

- Thermal impact studies

- Inerting studies

- Massive sensitivity studies

- 0D-1D rapid models

- 3D detailed models

- Making the type of studies suitable for the need expressed

-

-