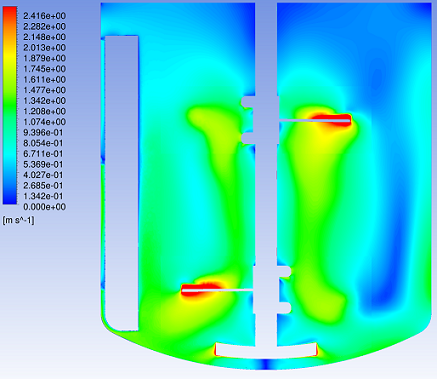

Homogenise a waste mixing tank

Orano can provide its expertise to model the homogeneity of tanks of waste with varying density and particle size containing a liquid-solid two-phase suspension.

-

Homogenising a tank of waste with varying density and particle size requires the following:

- Identify the tank design and efficient blades

- Cover the mechanical loads on the agitation shaft and tank heating

- Minimise agitation energy

- Guarantee suspended solids

- Understand the complex physical phenomena at play: 3D fluid dynamics in a rotating domain, turbulence, fluid-particle and particle-particle interactions.

-

Orano has developed a modelling methodology:

- established using artificial intelligence driven using 1000 simulations

- confirmed by comparing with experimental data from scientific literature and mock-ups especially designed by Orano.

The due representativeness of the method was:

- demonstrated in terms of agitation power and solid concentration profiles in the tank

- confirmed by an independent university audit.

The results obtained can be used for:

- an instantaneous comparison with a precision of ~10%

- quick calculations for pre-sizing studies

- significantly reducing sizing costs in the preliminary stages of projects.

- Expertise in the field of agitation and modelling

- Operational FLUENT physical model applicable to all types of agitated Newtonian suspensions

- Instantaneous AI model with a precision of 10% (in the applicable domain)

-

- Two-phase liquid-solid agitation in an agitated tank,

- Confirmed by comparing with experimental measurements,

- Quick calculations with a precision of 10%,

- An independent university audit confirming the method,

- Surrogate Model based on Artificial Intelligence,

- Costs and deadlines reduced from the preliminary stages of projects.

- Two-phase liquid-solid agitation in an agitated tank,

-

-