Designing a laboratory in a nuclear environment

Orano defines sites to meet requirements, sizes, constructs and commissions active laboratories hosting standard or advanced OTS analytical equipment.

-

- Clearly define needs in terms of flows, and the frequency and types of analyses required, with the operator

- Identify which analytical equipment must be adapted or modified to cover:

- analytical needs for radioactive solutions/effluents/sludges/solids

- the need for a guaranteed life for equipment in irradiating conditions

- the need to protect operators and facilities from irradiating and contaminating materials,

- the proper performance of procedures, quality targets, obligations defined by authorities and regulations.

- Analyse organisational and human factors to allow operators to work in suitable ergonomic, safe and secure conditions.

These phases must also take the following into consideration:

- potential integration in current facilities,

- the changing analytical needs of customers,

- changing analytical and measuring techniques.

-

Orano provides various types of services for laboratories:

- A package solution from designing the laboratory to commissioning,

- Support with defining needs (types of chambers, analytical equipment, sample management, etc.),

- Studies focusing on how to use OTS equipment in a nuclear context followed by the validation of a prototype at our facilities,

- Design studies for customised containment chambers (operability, maintenance, waste management, ventilation, etc.),

- Existing sizing verification studies for laboratories relating to new needs,

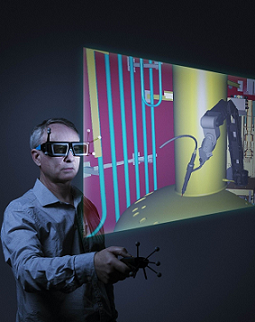

- Platforms, mock-ups and tools which are available or must be provided to train future facility operators.

- A customised service able to meet your needs and adapt to your requirements: from defining needs to providing a full solution

- An optimised design based on half a decade of experience in laboratory design and operations

- Experience based on projects completed for internal and external customers, in France and abroad

- Centres and infrastructures able to test prototypes in real conditions and validate/qualify inactive prototypes

-

- Operating nuclear laboratories (product quality, RCD and DEM, performance checks, environment, medical, asbestos)

- Shielded chambers with remote manipulators or tweezers, Glove Boxes, fume hoods

- Designed to ensure easy maintenance and operations for analytical equipment

- Samples can be taken and transferred from the process location to the analytical system

- Management of liquid and solid laboratory effluents

- Inline process monitoring (FXL, spectrophotometer, etc.)

- Multiple analytical techniques adapted to the nuclear sector for liquid and solid samples (ICP-MS, K-EDGE, FXL, Gamma spectrometry, SSA, furnaces, etc.)

- ALARA policy and consideration of ergonomic aspects when adapting analytical equipment for chambers

- Operator training

-

-