Modelling complex industrial systems

Sizing, optimising complex equipment/installations, supporting conventional or nuclear safety demonstrations and operation diagnostics on new or existing equipment.

-

Analyse complex physical phenomena with the right tools and with consideration of the physical domains and their couplings (chemistry, thermal, fluid, two-phase, etc.).

Develop new processes or adapt existing processes (process core) requires extensive design work to:

- Analyse physical phenomena

- Analyse equipment operation

- Optimise systems or the topology of parts

- Extrapolate (scale factor or time)

- Interpret tests (calculation/test complementarity)

- Interpret degraded operation

- Test and prioritise design concepts

- Quickly test new installation operating points

-

Modelling is a perfectly suited tool that relies on the development of specific models to complete the possibilities provided by “industrial” software.

With our multidisciplinary expertise, we develop digital models that fit your needs, based on upstream analysis to target the dimensioning physical phenomena.

The Orano modelling team has the capacity to develop complex models thanks to their mastery of:

- Software to couple the physical phenomena to be modelled,

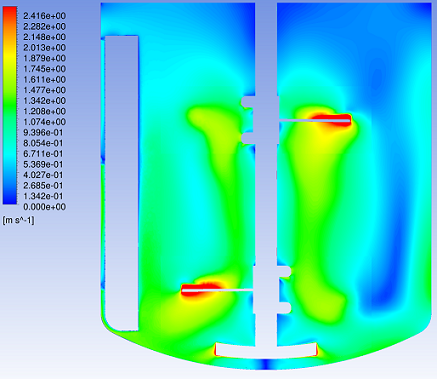

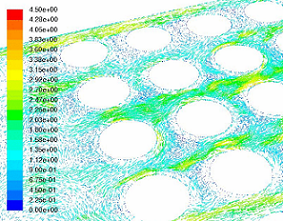

- 3D software to analyse local phenomena in more detail.

- Expertise in identifying, analysing and modelling the main phenomena in complex physical systems

- A variety of modelling tools, implemented according to client needs

- High computing power (more than 500 processors for CFD calculations and a dedicated AI server)

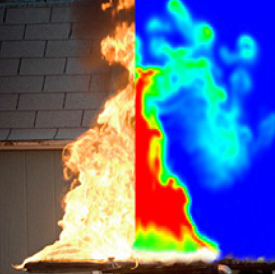

- Diversity of phenomena studied in chemical, thermal engineering and fluid/fire mechanics

-

- Design tailored to the specific need following analysis of phenomena

- Assistance in designing, dimensioning, optimising, diagnostics and verification of performance for process equipment, buildings, etc.

- Technical support for design/conventional and nuclear safety demonstrations

- Technical assistance on topics involving complex and coupled multi-physical phenomena

- Computing power in the hands of experienced engineers

- Mastery of the ASPEN software suite and 3D software programs (FLUENT, ANSYS thermal, COMSOL, FDS)

-

-